GARD Plasticases are experts in the field of foam conversion.

Whether your project requires a standalone foam design or a protective case with bespoke foam insert, you’ve come to the right place. The 3 most popular grades of foam we work with are HLB and LD18 and LD45 grades of Plastazote. We also offer nylon covered open cell foam in a range of colours and static-dissipative foam.

Our HLB (high load bearing) foam has an open cell structure offering premium protection, with an average net piece density of 20-22 Kg/m³. Nominal hardness is 120-160 Newtons and it has a minimum tensile strength of 70 Kpa.

The LD18 and LD45 Plastazote foams are cross-linked which increases stiffness and provides higher-level performance. They have densities of 18Kg/m³ and 45Kg/m³ respectively.

What foam grade would we recommend for you?

This depends on a few key factors including what industry your kit is used for, the environment it will be exposed to and also the weight and type of product that is to be housed in foam.

For example, if you had a piece of diagnostic equipment that requires protection, but is exposed to moisture, the best option would be either the LD18 or LD45 grades of Plastazote. These closed cell foams repel water and can be wiped clean leaving your plastic case and foam in top condition each time it is used.

How do we manufacture it to your required design?

Our methods for cutting foam include routing, water jet cutting and die cutting.

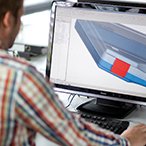

This enables us to supply plain sheets cut to size through to detailed intricate designs taken from a CAD drawing.

For us to cut your bespoke foam you can send a DXF or PDF with measurements, or if this is not possible you are welcome to send a set of the kit and we can take measurements and arrange the layout on site at GARD.

For further information please feel welcome to contact our sales team sales@gardplasticases.com.